Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

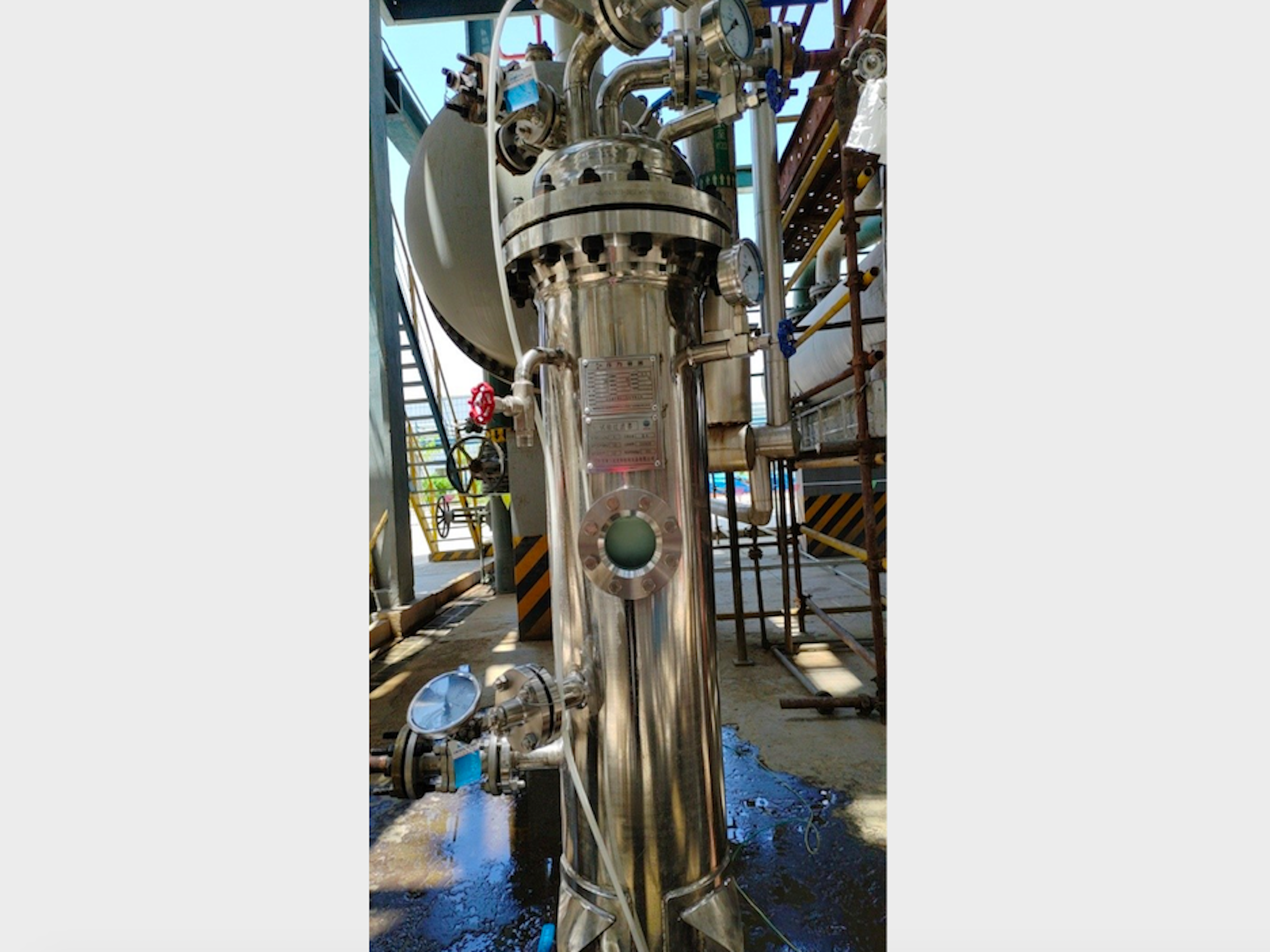

LCDF series multi-column automatic backwash filter

LCDF series multi-column automatic backwash filter

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

Product introductionLCD

Series multi-column automatic backwash filter is widely used in coal-to-gas, metallurgy, chemical, petroleum, papermaking, medicine, food, mining, electric power, urban water supply fields. Such as industrial condensate, washing water, wastewater, circulating water filtration, metallurgical industry continuous casting water system, blast furnace water system, hot rolling high-pressure water descaling system is an advanced, efficient and easy-to-operate automatic filtration device

Working principleThe

LCD series multi-column automatic backwash filter produced and developed by our company is composed of a shell, a filter element, a backwash rotating mechanism, a differential pressure controller and an electronic control part.

The filter element adopts a high-strength Johnson wedge-shaped filter or a metal braided mesh filter element, and the filter element is automatically cleaned through differential pressure control and timing control. When impurities accumulate on the inner surface of the filter element and cause the inlet and outlet pressure difference to increase to the set value (e.g., 1kgf/cm2), or when the timer reaches the preset time, the electric control box sends a signal to drive the backwashing mechanism. When the backwash suction cup mouth and the filter inlet are facing each other, the blowdown valve is opened, at this time, the system is depressurized and drained, and a negative pressure area with a relative pressure lower than the water pressure on the outside of the filter element appears on the inside of the suction cup and the filter element (the backwash pressure difference is controlled at 3~4 times of the filter pressure difference value), forcing part of the net circulating water to flow into the inner side of the filter element from the outside of the filter element, and the impurity particles adsorbed on the inner wall of the filter element enter the disc with the water flow and are discharged from the sewage valve.

Product specifications and technical parameters

Reference accuracy: 200 micrometers

Fields of application

|

The metallurgical industry

Oilfield sewage filters suspended solids in oilfield sewage

|

Chemical and petrochemical

Power plants and thermal power plants |

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component