Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

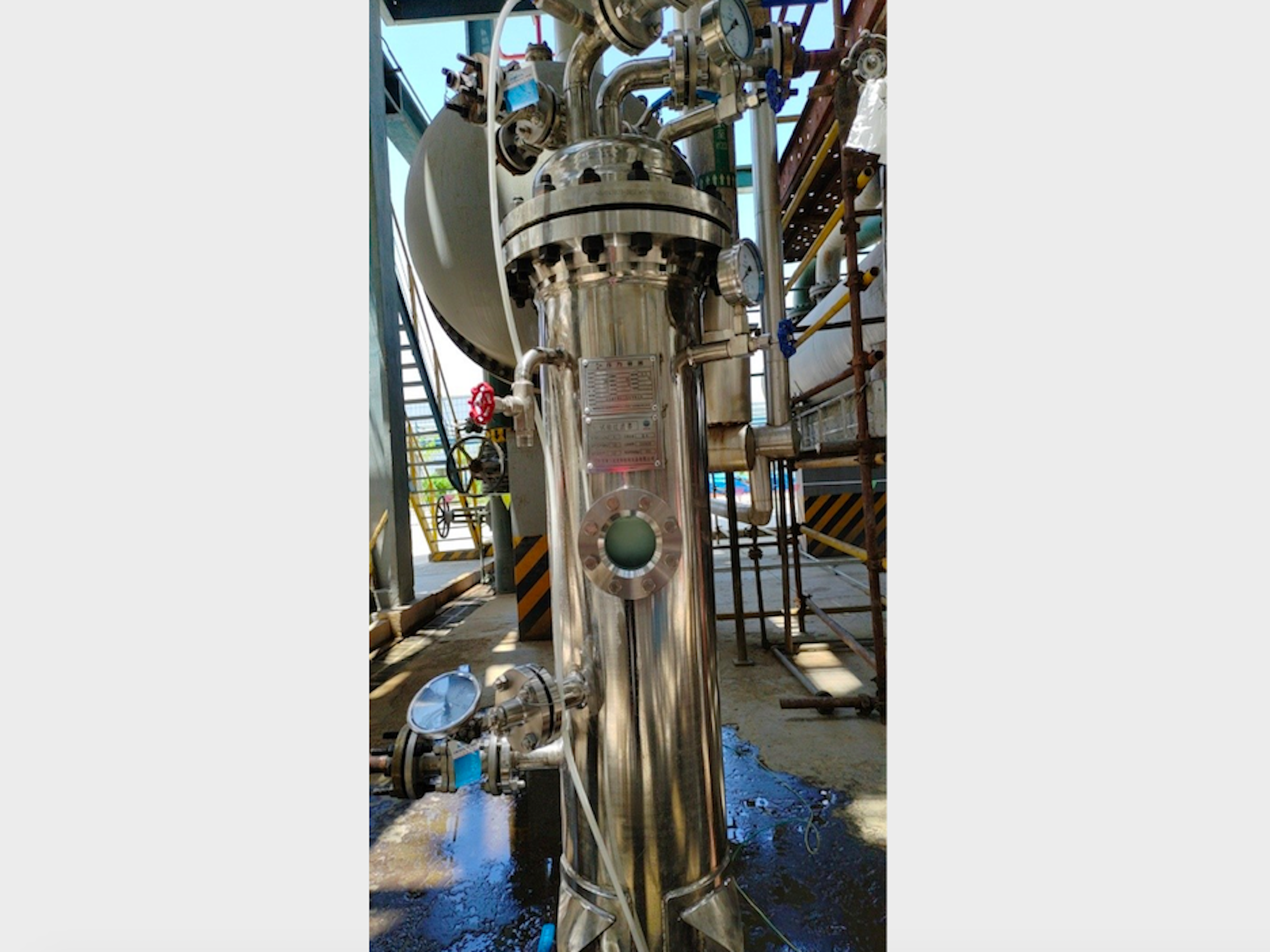

Large capacity filter element filter

Large capacity filter element filter

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

In industrial production, for high impurity content, especially when the fluid contains a large number of soft deformed particles, the traditional automatic filter, whether backwashing or self-cleaning form is not suitable, Blue Ocean Riverflow's FSC3 series filter is an ideal choice.

The filter element used inside the filter is designed and developed by 3M Company of the United States, with a single filter element filtration area of up to 14.5m² and a single filter element holding capacity of more than 10 kg, so far, it is the highest single filter element in the world. Technical Specifications:

●Design pressure: 6~40Bar ●Design temperature: up to 140°C

● Filter Material: CS, 16MnR, SS304, SS316, Ti, Hastolloy, PFA, PTFE Coating ● Sealing ring material: nitrile rubber, silicone rubber, PTFE, stainless steel winding, graphite and other options ● For the petrochemical industry, the filter can be designed and manufactured according to ASME or GB150 standards

● In continuous production, parallel switching, modularization and mobile filtration systems can be provided to meet the requirements of continuous production

The filter is especially suitable for occasions where the filtration accuracy is in the range of 1~25μm, requiring high filtration efficiency, large impurity retention and long service life, as well as in the process that requires long-term continuous filtration, so it is particularly widely used in the following industries: ●Filtration of desulfurization and decarburization solution in petrochemical industry● Filtration of desulfurization and decarburization amine solution in natural gas-to-methanol process●Filtration of closed-circuit circulating water●Filtration of decolorizer and filter aid●Filtration of pharmaceutical distilled water● Filtration of fuel oil●Precision filtration of electroplating solution

Case Study: Amine Filtration

Amine liquids in the oil and gas industry are commonly used for desulfurization, and the increase in solids in amine liquids will directly lead to liquid foaming and reduced production efficiency; The use of extra-large dirt-containing filters can greatly increase the changeover time, which reduces the chance of workers being exposed to harmful sulfur gases, and also greatly reduces the downtime due to the replacement of filter elements; As a result, amine depletion and disposal costs are reduced.

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component