Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

Folding membrane filter element

Metal sintered mesh filter element

Metal wedge wire mesh filter element

Sintered metal powder filter element

Metal felt folding filter element

Modular automatic self-cleaning filter system

Hand brush type self-cleaning filter

Focus on us

Public Number

Tiktok

Quick Hands

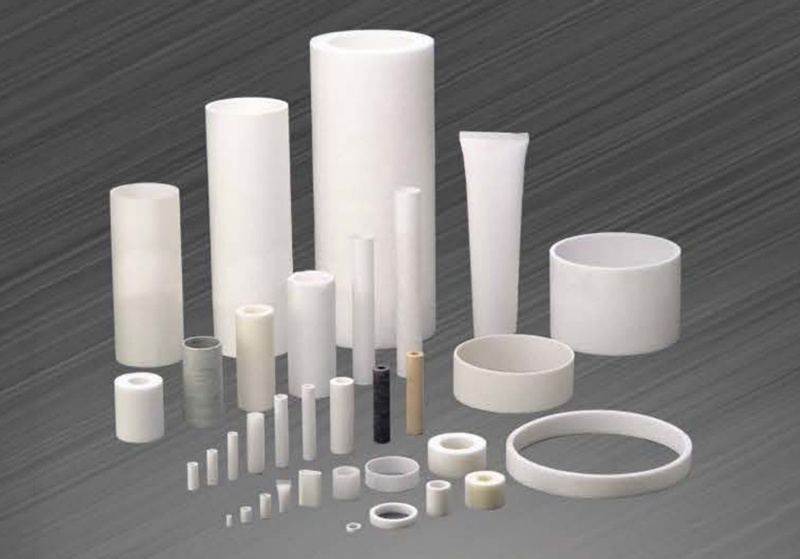

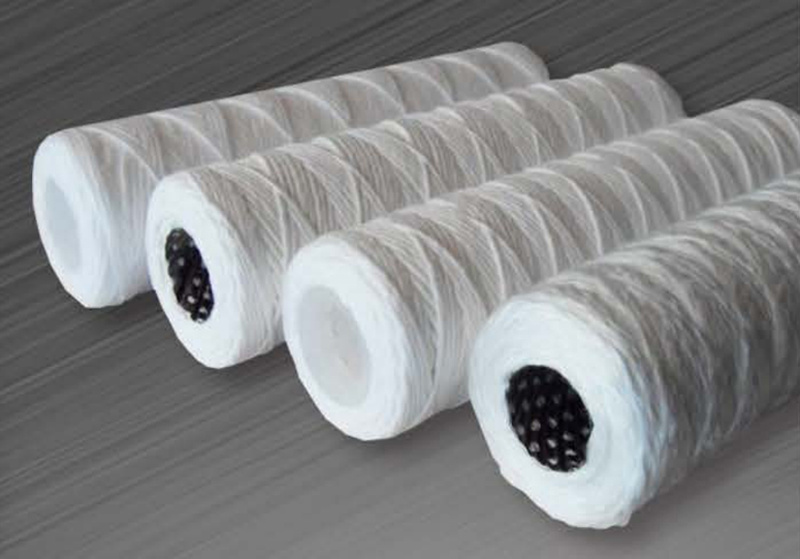

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component