Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

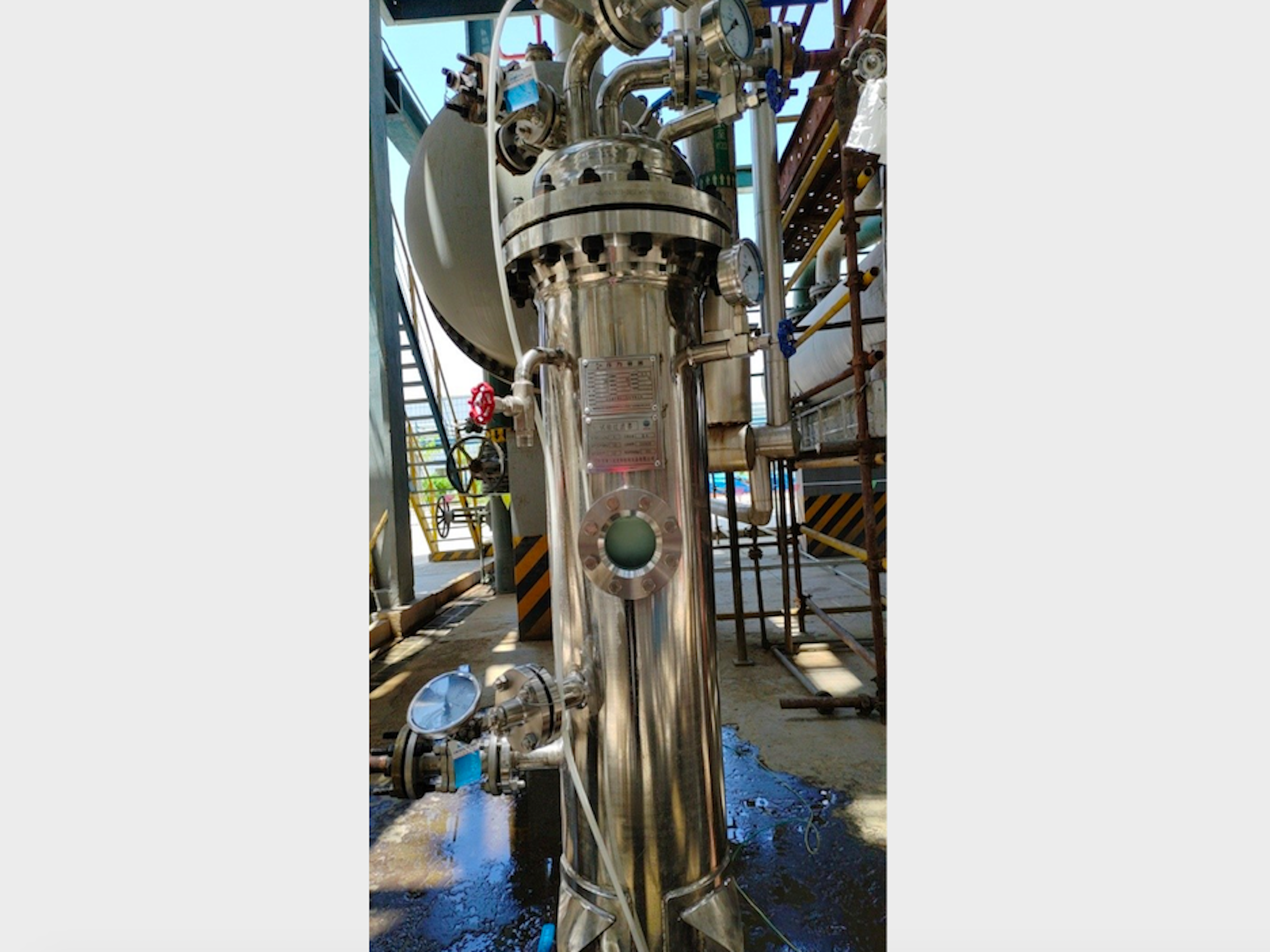

Hand brush type self-cleaning filter

Hand brush type self-cleaning filter

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

Product Introduction

The Hand Brush Filter is a manual cleaning filter with a maximum filtration accuracy of 50 microns. Its main structure is to install a set of brushes inside the filter screen and a blowdown valve on the filter end cover. When cleaning, as long as you open the blowdown valve and shake the handle outside the end cover at the same time, you can drive the brush to brush off the dirt and impurities on the filter screen, and discharge the filter through the blowdown valve. There is no need to cut off the flow during cleaning. There are three types of hand-cranked brush filters: Y-type, F-type, L-type.

How it works

When the impurity particles in the water flow continue to accumulate on the inner surface of the filter, the pressure difference between the inlet and outlet of the filter increases, and the on-site operator can understand the pressure difference through the inlet and outlet pressure gauges, when the pressure difference reaches 0.05MPa, the operator opens the sewage valve in time, shakes the handle on the filter cover, drives the brush in the filter cartridge, removes the impurities accumulated on the surface of the filter screen, and discharges it through the sewage valve.

Features

· Simple structure design, high filtration efficiency and high reliability;

· Brush type non-stop cleaning;

· Large filtration area, minimal pressure loss;

· Continuous flow of cleaning, especially suitable for 24-hour non-stop systems;

· The installation is flexible, it can be installed horizontally or adapted to vertical installation.

Application field

Installed on the pipeline to filter out solid impurities such as rust and sand particles in the fluid, protect the equipment on the pipeline from wear and blockage, so that the machinery and equipment,compressors, pumps, valves, instruments, etc. can work and operate normally, so as to achieve a stable process and ensure safe production.

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component