Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

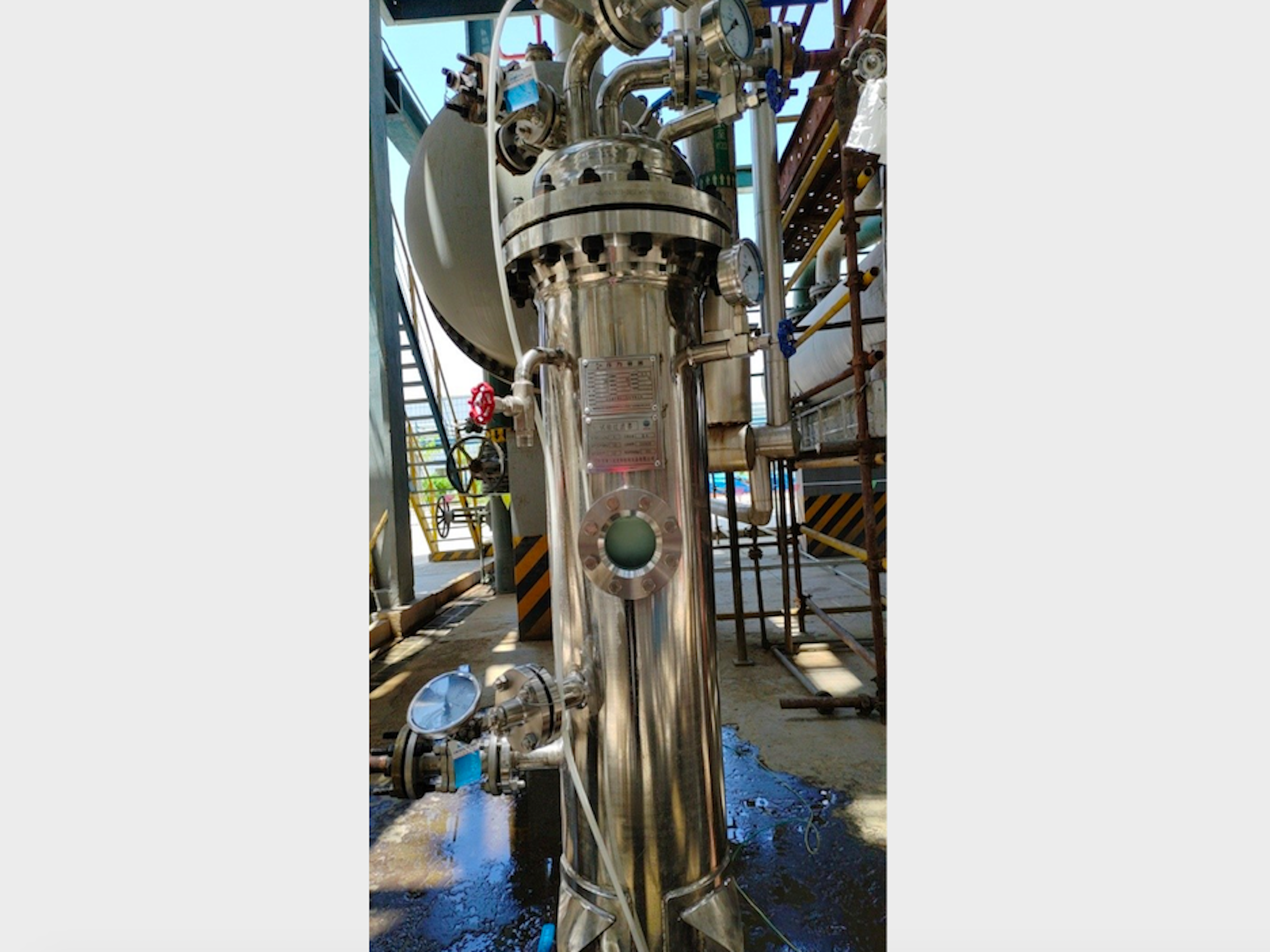

Drain the slag filter

Drain the slag filter

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

Features:

Digest and absorb foreign advanced technology and innovate independently, and develop a new generation of candle filter. It is characterized by energy saving and environmental protection, resource saving, stable and safe operation, and no spillage. The filter element can be automatically regenerated online, and the key operating parameters can also be customized online, the system has a wide range of applications, and the operation process is mature and reliable.

Performance Advantage Characteristics

1) The system runs in parallel, which can realize the sequential cleaning and continuous operation of multiple filters to ensure that the system does not stop running, and the process water can be recycled, and the addition of water treatment agents and filter aids is eliminated, which greatly reduces the production cost.

2) The skid is supplied as a whole, with a small footprint, space-saving, reliable and simple installation and maintenance.

3) The skeleton and horizontal hanging pipe of the filter element are made of high-quality materials, which improves the pressure bearing strength of the filter element and is corrosion-resistant, especially fluoride ion and chloride ion corrosion, and has a long service life of more than 10 years. (Know-how).

4) The length of the filter element can be adjusted, the module design, the disassembly and assembly are fast, the structure is low, and the filter is suitable for different height specifications. (Know-how)

5) The filter medium of the filter element is a fine membrane structure. (Know-how)

6) The upper part of the filter tank is equipped with an anti-blowout vibration buffer device. (Know-how)

7) The upper part of the filter tank is equipped with an anti-swelling device for the horizontal hanging tube of the filter element. (Our know-how)

8) The equipment fully considers the particularity of the wastewater body, and the anti-corrosion requirements are fully considered for the liquid contact part, so that the system operation is stable and reliable, and the maintenance cost is low.

9) On-line cleaning, which can realize complete dry slag cake removal (1 second to completely remove the filter cake), and can disassemble and overhaul the system equipment unit online, without affecting the normal operation of the system.

10) The whole system is closed and fully automatic, the process is short, the adaptability to the solid content of the incoming material is strong, the effluent water quality is stable, and the dry residue is discharged, which is conducive to the recovery of slurry and solid impurities, and can be automatically backwashed, and the labor operation cost is low. Energy saving and emission reduction, no secondary pollutants are generated, and the system covers an area of a little more than 1/3 of the traditional system (the same treatment capacity), and the power consumption is 2/3 of the traditional system (the same treatment capacity).

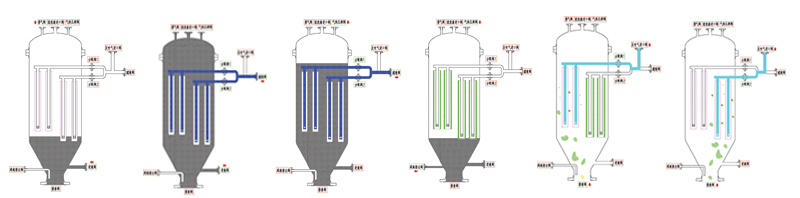

How it works

When the liquid passes through the filter, the particle impurities are blocked on the outer surface of the filter element, and accumulate to form a filter cake, so that the pressure difference between the inlet and outlet of the filter gradually increases, when the pressure difference reaches a certain default value (150KPa), the filter cake reaches a certain thickness, at this time, the filterable flow rate of the filter element is getting smaller and smaller, the controller starts the backflushing action, and when the filter element is backblowing, the filter cloth expands rapidly from the folded form to a cylindrical shape, so that the filter cake layer is completely peeled off, and the residue is discharged, and then the sewage valve is closed and the inlet valve is opened. Return to normal filtering.

Main trial scope

Applicable industries: petrochemical, beverage, fine chemical, oil, water treatment, titanium dioxide, electric power, polysilicon, etc.; Applicable fluids: resin, recycled wax, cutting oil, fuel oil, lubricating oil, machining cooling oil, transformer oil, bone glue, gelatin, citric acid, syrup, beer, epoxy resin, polyethylene glycol, etc.

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component