Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

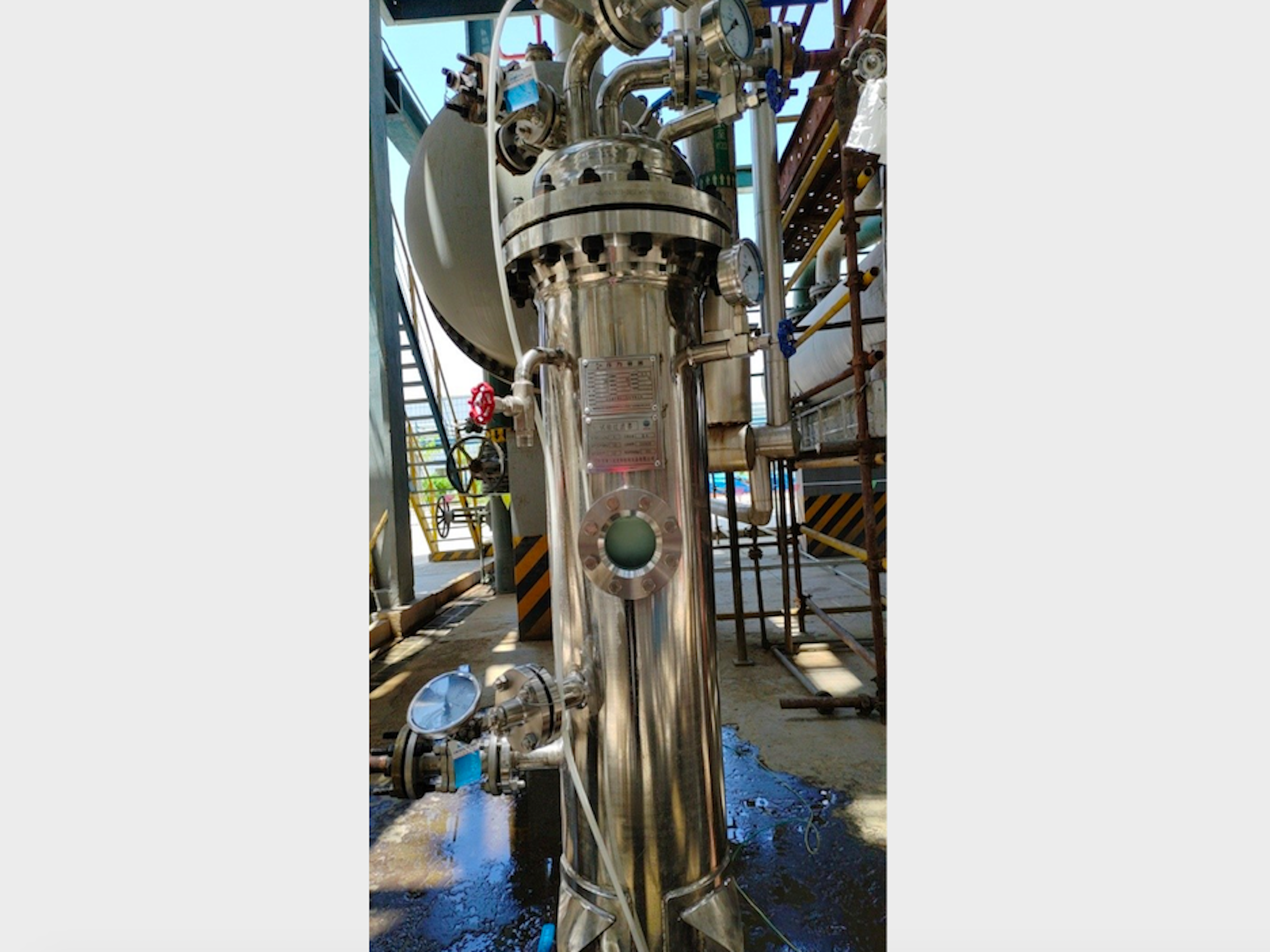

LCGF series scraper type automatic cleaning filter

LCGF series scraper type automatic cleaning filter

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

Product Introduction

LCGF series scraper self-cleaning filter is a new type of high-efficiency scraper self-cleaning filter, which automatically removes particulate impurities on the inner surface of the filter element through mechanical scraping, and can be continuously filtered online. The LCGF filter is mainly designed for high viscosity filtration, suitable for viscosity up to 800,000mPa.s, accuracy range of 30-1500 microns, precise filtration, can scrape impurities off the surface of the filter element as quickly as possible, so as to efficiently remove more impurities, suitable for the filtration of water and various viscous liquids. The LCGF filter is designed and manufactured in accordance with the standards of high performance, high quality and high reliability of Xinli Purification, and has reached the world's first-class quality.

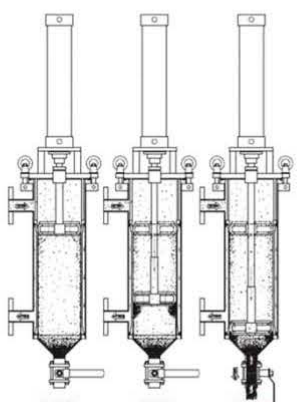

Working principleThe

water to be treated enters the body from the water inlet, and the impurities in the water are deposited on the stainless steel wedge-shaped net, resulting in a pressure difference. When the differential pressure reaches the set value, the electric controller gives the control valve and the drive motor signal, triggering the following actions: the motor drives the brush to rotate, the filter element is cleaned, and the control valve is opened for sewage discharge, the whole cleaning process only lasts for tens of seconds, when the cleaning is over, the control valve is closed, the motor stops rotating, the system returns to its initial state, and begins to enter the next filtration process.

Features

Filtration → cleaning → drainage

Features

· Up and down reciprocating scraping, directly scraping away impurities, good at filtering viscous liquids to remove viscous suspended impurities;

· The structure is simple, easy to disassemble and assemble, after removing the scraper, the filter element can be easily removed, and the inside is easy to clean;

· Fully automatic operation, continuous on-line filtration, ending the heavy filter element replacement and cleaning work;

· It does not produce one-time discarded filtration consumables, saving the cost of consumables and environmental protection treatment;

· The filtration pressure loss is very small, the flow rate is stable, the energy consumption is saved, and the process is continuous and stable;

· Closed filtration to prevent the leakage of hazardous materials, which is conducive to safe production and employee health;

· The discharge of waste liquid impurities has a high concentration and can be recycled, reducing the loss of high-value materials;

· A variety of advanced control systems are optional, powerful, efficient operation and high reliability;

· Choose world-renowned brand components, high reliability, low operating costs;

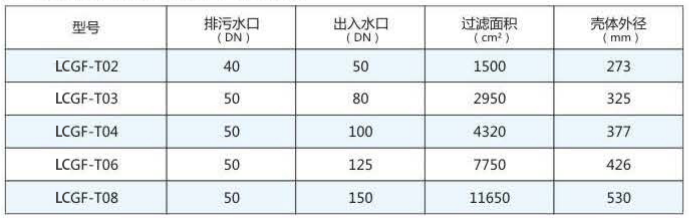

Product specifications and technical parameters

Filter details

Application fieldsApplication

fields: petrochemical industry, fine chemicals, oils, water treatment, papermaking, etc.

Applicable liquid types: resins, coatings, polymers, adhesives, citric acid, fermentation broth, chitosan, cosmetics, agarose (gel), perol, steroids, cereal syrup, wet-end additives, pigments, lubricants, rubber, ethanol, mixed oils, edible oils, fruit juices, diesel and other silicone solutions, soaps, sorbitol, steroids, cereal syrup, wet-end additives, pigments, lubricants, rubber, ethanol, mixed oils, edible oils, fruit juices, diesel, etc.

Chemical and petrochemical: filter and remove impurity particles in chemical media to improve product quality. Sealant: It is used to filter impurity particles in the colloid to ensure the high quality of the product

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component