Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

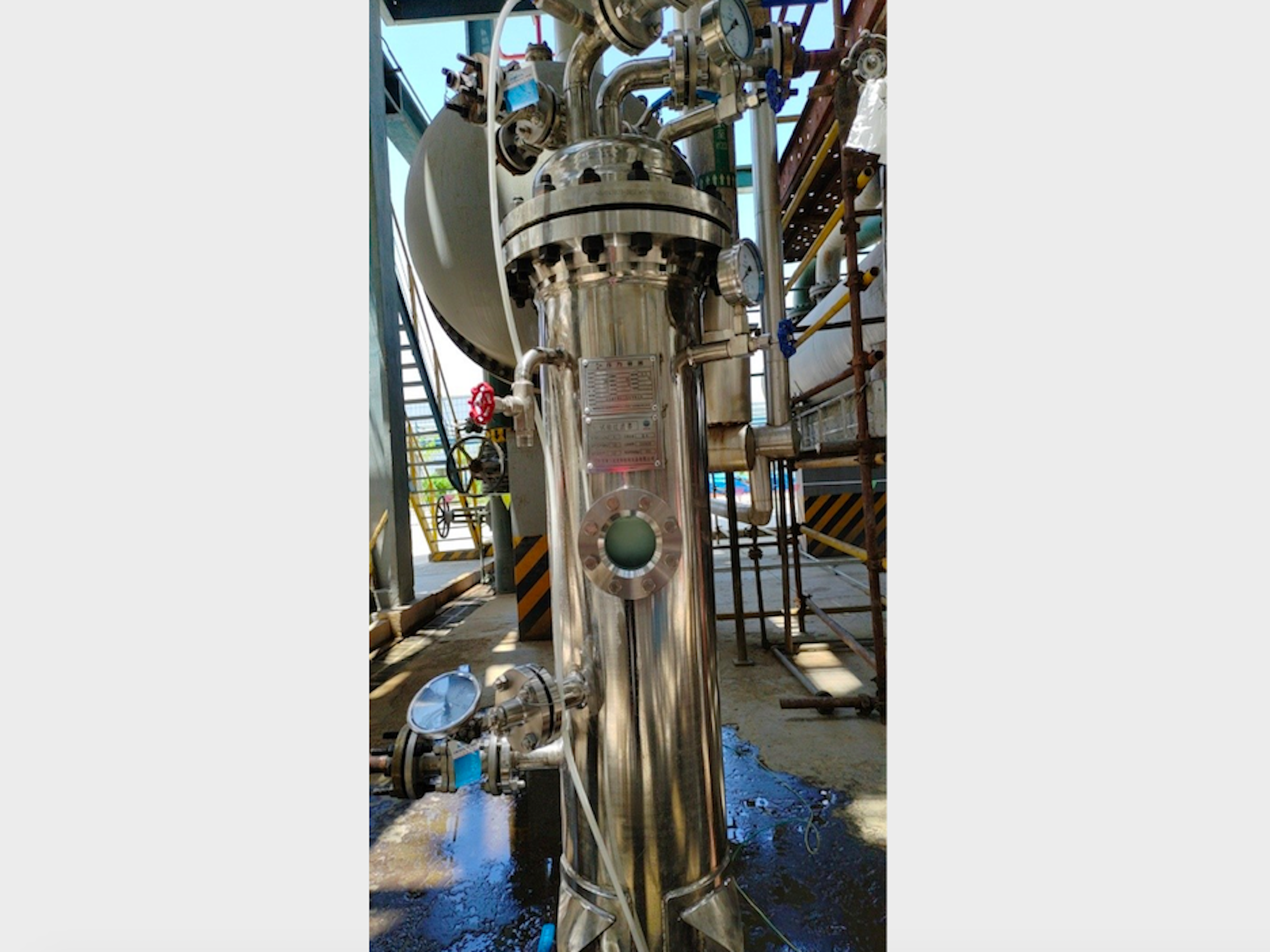

Candle filter system

Candle filter system

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

Product Introduction

The candle filter system developed and produced by our company has a novel filter structure, the filter element adopts a horizontal pipe suspension type, and the clean liquid flows out directly from the horizontal pipe, which optimizes the process links such as backflushing and pressing of the filter element of the partition split filter.

The filtrate enters the filter from the inlet of the original solution, the impurities are intercepted by the filter element, and the clear liquid flows out from the outlet.

The filter stops filtering, and the compressed gas is introduced into the tank, and under the action of the compressed gas, the solution in the tank continues to be filtered (according to the quality requirements of the medium and the clear liquid, the filtrate can be treated in different ways) After the filter is pressed, it can continue to rely on the compressed gas or the residual liquid pump to discharge the residual liquid, and the compressed gas is regularly introduced into the filter element from the outlet of the clear liquid, and the impurities on the metal filter element are blown off the filter bag filter element, and the compressed gas makes the filter bag expand and shake, and the impurities fall off with the shake. The impurities on the filter element are blown off by the gas, and the detached impurities are discharged from the discharge port at the bottom of the filter.

Features

· Fully enclosed operation, no environmental pollution;

· Easy to operate, safe and reliable, automatic and manual;

· Greatly reduced labor and water consumption;

· The filter element can be self-cleaning, in-line cake removal and dehydration;

· The residual liquid can be filtered out online to achieve dry residue discharge;

· Filter aids can be used to improve filtration accuracy;

· Filter element material: 304, 316L, pure, polymer material, etc.;

· Filter element form: metal powder sintering, metal sintered felt, metal multi-layer sintered mesh, polymer filter cloth, filter membrane, etc.

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component