Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

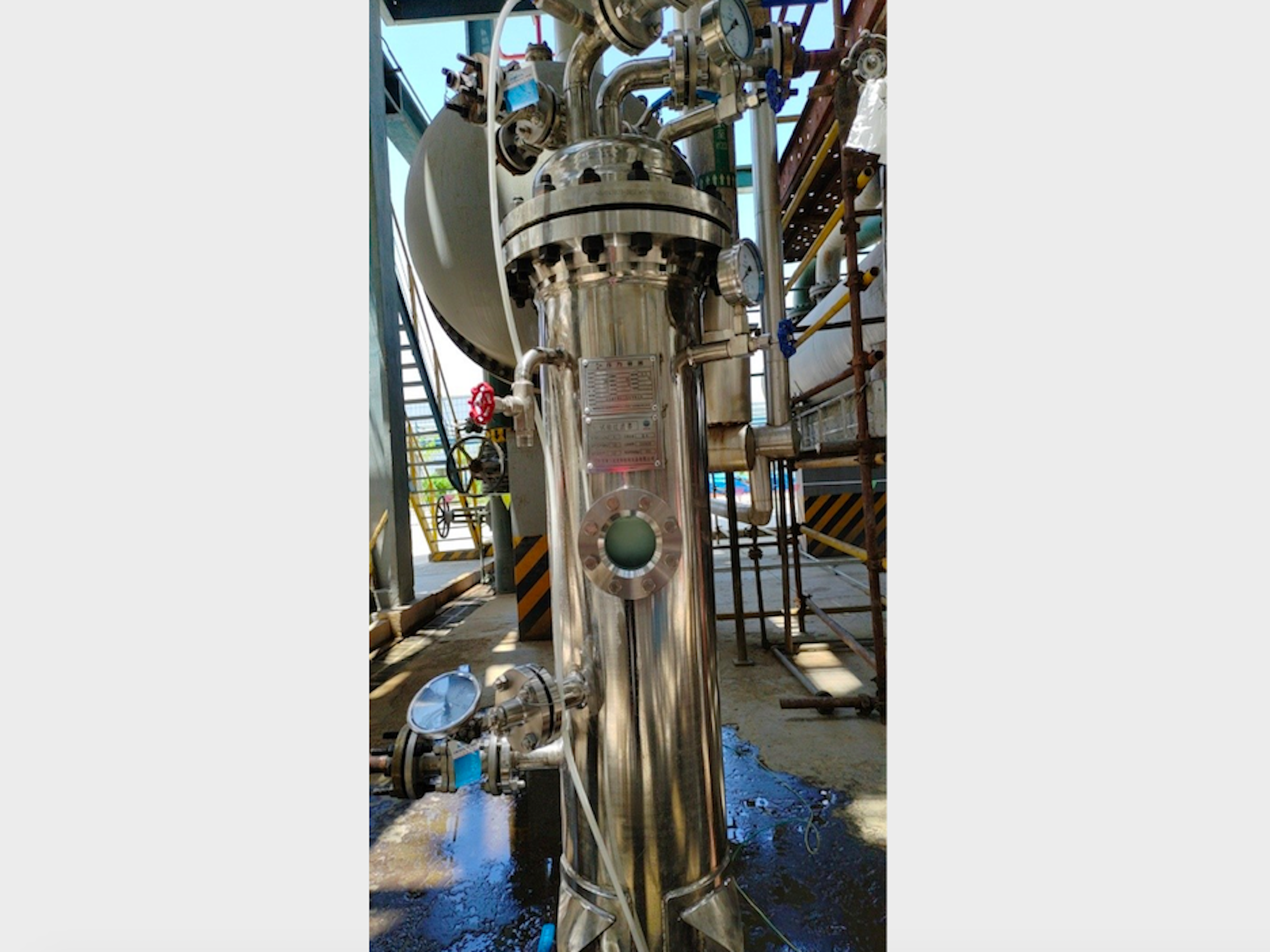

Bag, pipe, basket filter

Bag, pipe, basket filter

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

Product Introduction

Bag filters have been widely used in industries around the world and have become a standard. Customers can meet the demanding requirements of different applications according to our standard single-bag filter or multi-bag filter system.

Single-bag filters provide high-performance units with high accuracy and economical filtration units for pre-filtration.

Multi-bag filter can provide 1-40 filter elements for selection, diversified and advanced filter design, precision filter bag, automation combination, to provide you with the most optimal solution.

Pipeline filters are products that separate solid particle impurities from fluids, improve product purity, and protect downstream equipment (compressors, pumps, instruments) from working safely.

Pipeline filters are divided into Y-type filters, T-type filters, basket filters, etc. according to different forms.

The basket filter uses a metal filter basket as the filter element, which is mainly composed of a pipe, a cylinder, a filter basket, a flange, a flange cover and fasteners. Installed on the pipeline can remove large solid impurities in the fluid, so that machinery and equipment (including compressors, pumps, etc.) and instruments can work and operate normally, so as to achieve a stable process and ensure safe production.

When the liquid enters the filter basket through the cylinder, the solid impurity particles are blocked in the filter basket, and the clean fluid passes through the filter basket and is discharged by the filter outlet. When it is necessary to clean, unscrew the screw plug at the bottom of the main pipe, drain the fluid, remove the flange cover, and reload it after cleaning. Therefore, it is extremely convenient to use and maintain.

Features:

It has the advantages of compact structure, large filtration capacity, small pressure loss, wide range of application, convenient maintenance, low price, etc., and its main applicable materials are: weak corrosive materials in chemical and petrochemical production, such as: water, oil, ammonia, hydrocarbons, etc.; Corrosive materials in chemical production, such as: caustic soda, soda ash, concentrated dilute sulfuric acid, carbonic acid, aldehyde acid, etc.; Low-temperature materials in refrigeration, such as: liquid methane, liquid ammonia, liquid oxygen and various refrigerants; Materials with hygienic requirements in food and pharmaceutical production, such as beer, beverages, dairy products, syrups, etc.

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component