Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

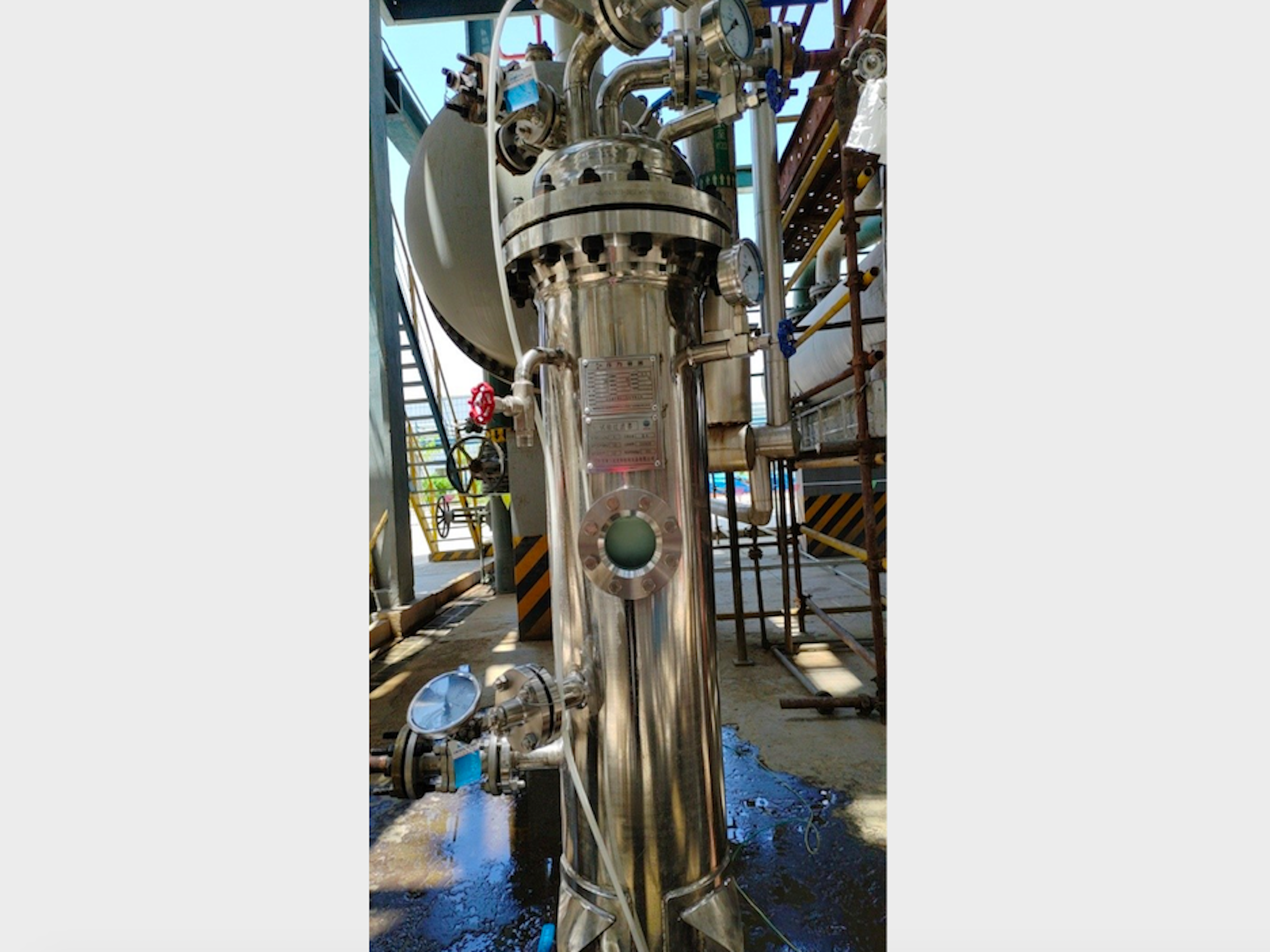

LCJF series precision filter

LCJF series precision filter

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

Product Introduction

Precision filter (also known as security filter), the simplified shell is generally made of stainless steel, and the internal sintered mesh, sintered felt, powder sintered PP meltblown, wire sintered folding, activated carbon filter element and other tubular filter elements are used as filter elements, and different filter elements are selected according to different filter media and design processes to meet the requirements of effluent water quality. With the continuous development of the filtration industry, more and more industries and enterprises have applied precision filters, and more and more enterprises have joined the precision filter industry.

Features

· The optimal welding method is selected to ensure that the quality of each weld meets the GB150 technical standard, and that the filter itself and the filtration process are 100% leak-free;

· Sandblasting or polishing of the inner and outer surfaces of the product;

· The filter element has high porosity, low filtration resistance and high permeation efficiency;

· The filter element has good chemical stability, acid and alkali corrosion resistance, and oxidation resistance;

· There is no particle shedding phenomenon in the filter element itself, which will not cause secondary pollution of the stock solution;

· The filter has good mechanical properties, can be pressed and filtered, and is simple to operate;

· Low differential pressure, small footprint, large flow rate;

· The filter element has strong anti-microbial ability and does not react with microorganisms;

· It can be cleaned and regenerated online, which is easy to clean and has a long service life.

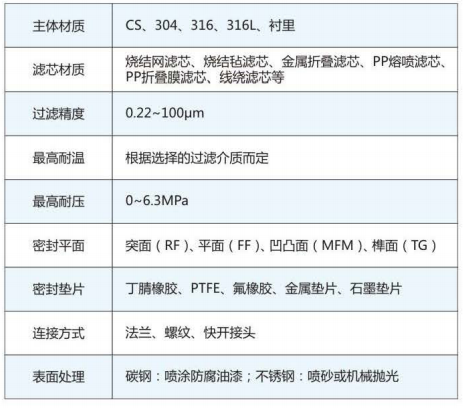

Product specifications and technical parameters

Fields of application

Precision filters are widely used in petrochemical, natural gas, coatings, paints, inks, medicine, bioengineering, automobile manufacturing, electronics, electroplating, food, beverages and other fields, and are ideal equipment for filtration, clarification and purification of various liquids.

Petrochemical and chemical industry: hydrogen peroxide, resin, lubricating oil, polymer, viscose, jet fuel and various oil products, catalysts, chemical fiber manufacturing process of various fluid purification, chemical intermediate products and chemical products separation and recovery;

Oil & Gas Industry: Gas Station, NG Filtration, Amine Liquid Desulfurization and Dehydrator Filtration, Natural Gas and Refinery Separation and Purification, Oilfield Water Injection, Repair, Acidified Liquid Filtration;

Coatings, paints, inks: latex paints, paint raw materials and solvent filtration, printing inks, printing inks and additives;

Pharmaceutical and bioengineering industries: infusion (LVP and SVP), pharmaceutical water, biological products, plasma, serum, various pharmaceutical intermediates, pharmaceutical raw materials, solvent filtration, CIP filtration, fermenter inlet and exhaust gas sterilization filtration;

Automobile manufacturing industry: electrophoretic paint, topcoat, superwater, pretreatment fluid, vehicle spray water, engine crankshaft manufacturing coolant, spray industrial gas and paint booth gas purification;

Electronics and electroplating industry: liquid crystal display, lithography machine, optical disc, copper foil, integrated circuit and other microelectronics and electronic products manufacturing process of various chemicals and treatment, electroplating solution, process gas purification and purification room gas filtration;

Food, beverage, liquor industry: process purification and aseptic treatment of wine, rice wine, liquor, beer, fruit wine, sake, fruit juice, tea beverage, soybean milk, dairy products, bottled water, edible oil, vinegar, monosodium glutamate and other food additives.

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component