Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park

Telephone:400-9957618

Mobile:13700091519

E-mail:lnlhcl@163.com

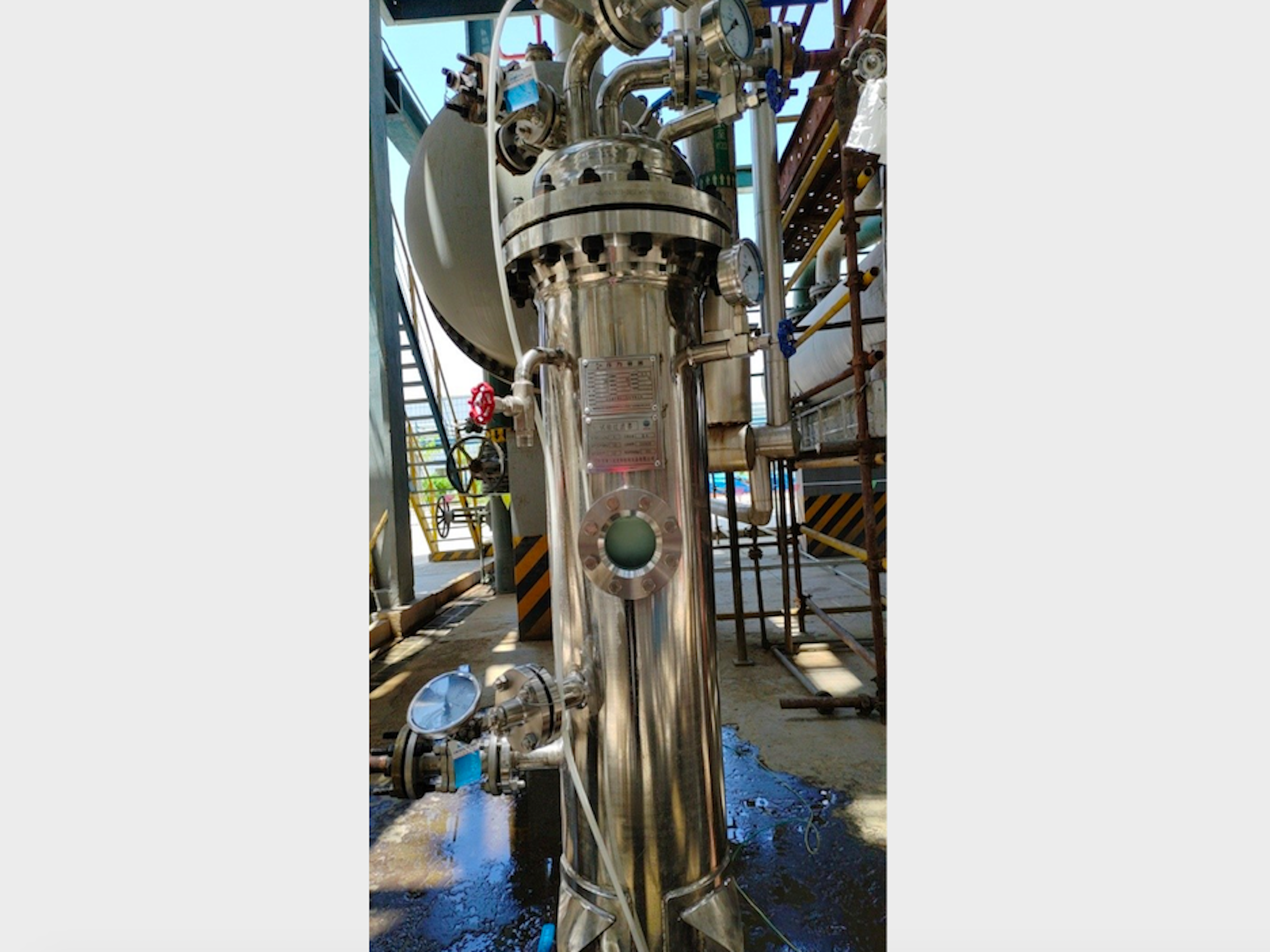

Modular automatic self-cleaning filter system

Modular automatic self-cleaning filter system

Classification:

Keyword:

Bag Filter System, Metal Filter System

Telephone:

Product Introduction

The modular automatic self-cleaning filtration system is a new type of filtration system developed and produced by our company with foreign advanced technology, mainly for the impurities of the medium in the process of petroleum, chemical, water treatment and other industries. The particle size of suspended solids is very small, and other traditional filtration methods can not be effectively removed, especially the characteristics of in-line cleaning, and special filtration methods are used to effectively remove insoluble matter in the system and other foreign substances introduced in the manufacturing and treatment process. The modular automatic self-cleaning filtration system is mainly composed of multiple sets of pipeline filters, differential pressure controllers, pneumatic valves and pipes, brackets, electric control boxes, etc.

The modular automatic self-cleaning filtration system is divided into a clean cavity and a turbidity cavity by a partition, and it is equipped with thousands of filter elements. The raw material flowing from the inlet passes through the filter element from the outside to the inside, and the impurities in it are trapped on the outside of the filter element, and the filtered cleaning material is discharged from the outlet through the net cavity. When the pressure difference between the inlet and outlet reaches the set value, each group of filters is cleaned separately and a group of filter inlet and outlet valves are closed. Open the blowdown valve and backwash valve to reverse-clean the filter element. After cleaning, switch to the next set of filters for cleaning. The whole flushing process does not affect the normal filtration of the system, the backwashing is convenient and fast, and the whole system can be operated manually or automatically through the control cabinet.

Features

· Continuous feeding function;

· The backwash effect is good;

· Good maintenance, low cost;

· Quick disassembly and assembly, convenient and small footprint;

· Adaptation to a variety of environments;

· It is suitable for all kinds of liquid materials.

Application field

petrochemical industry: diesel, raw oil filtration;

gasoline, naphtha, coking wax oil;

Water treatment: raw water, process water, clean water, cooling circulating water, spray water, papermaking turbid white water filtration.

Keyword:

Product Consulting

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component