Precautions for holding sintered felt at sintering temperature

Release time:

Sep 27,2021

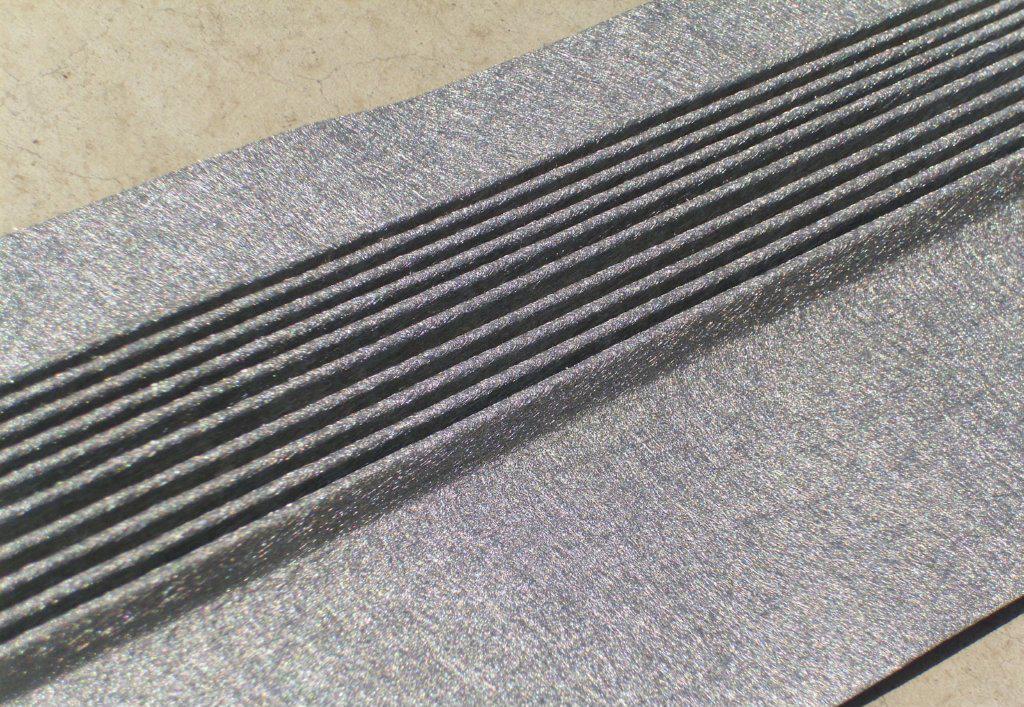

The sintered felt can continuously maintain the filtering effect of the filter mesh cloth, and has the characteristics of three-dimensional network, porous structure, high porosity, large surface area, pore size and uniform distribution. As a result, stainless steel sintered felt floors overcome the defects of metal gridding, concept and feature fragility. It makes up for the fragility and small flow of powder filtration products, and solves the characteristics of filter paper and filter cloth that are not temperature resistant and pressure-resistant, so stainless steel sintered felt has excellent filtration performance and is an ideal filter material with high temperature resistance, corrosion resistance and high precision.

The sintered felt is kept warm at the sintering temperature for a period of time, so that the densification of the green body that occurs during the sintering process is fully carried out, and the porosity of the product is shrunk and the transformation to the crystal has enough time. The length of holding time depends on the number and size of the sintered product. The density and magnetic properties of the product can be measured to determine the appropriate sintering temperature and holding time. With the increase of temperature, under the action of vacuuming, the gas discharge in the pressure billet tends to be complete.

For sintering in a protective atmosphere, argon gas should be filled into the sintering chamber to complete the sintering in a protective atmosphere. After argon is filled, the vacuum unit is stopped to reduce power consumption. When using chemical backwashes, no longer when. Purchase a recommended filter at a swimming pool supply store and pour the sand filter after the manufacturer's instructions. Remove the DE filter grid and soak in the appropriate chemical solution. Hold the spool valve. You should lubricate the O-ring once a year to remove the plunger and apply the lubricant.

Next article

undefined

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component