Familiarize you with the basics of candle filters

Release time:

Sep 01,2021

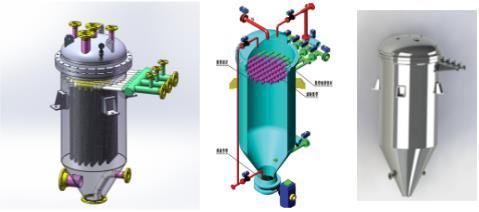

The internal composition of the candle filter:

1. Equipment internals include: filter element, filtrate header, header fixation, residual liquid elbow, etc.

2. The filtrate header is fixed with bolts and pipes by the fixing plate welded to the container shell, and there is a long hole in the fixing plate, which can be adjusted with a trace gap during assembly.

3. The connection and fixing of the filter element and the header are sealed by fine thread and packing, and then fixed by adding a lock nut.

4. The function of the residual liquid elbow is to drain the residual liquid in the container to the greatest extent.

The main properties of candle filters:

1. Fully enclosed operation, suitable for material filtration in the petrochemical industry, particle removal in the water treatment industry, and can also be used for the filtration of flammable, explosive, toxic or highly toxic dangerous products and food, biological products and drugs that are not allowed to be contaminated.

2. The structural design is reasonable, and it is convenient to assemble, disassemble and replace the filter element.

3. Because filter cloth, wire mesh, sintered metal, microporous membrane and other materials can be used as filter media, this filter can meet the needs of various users and has a wide range of use.

4. The filtration area of the equipment is large, which is suitable for the filtration of thinner slurry with a large filtration capacity.

5. The equipment is compact, covers a small area, and has high filtration efficiency.

6. When used for liquid clarification, this machine can also pre-apply or directly add diatomaceous earth, activated carbon and other filter aids to the slurry, so that the filtration rate is faster and the filtrate is clearer.

7. In the later stage of filtration, if the residual slurry at the bottom cannot be discharged back to the slurry tank, the residual slurry at the bottom can be pumped out by a pump, and then returned to the top cover of the filter in the center of the top, and evenly sprayed onto the filter pipe through the nozzle, and the residual liquid is filtered out through the input of compressed gas in the machine.

8. Because this machine can form a uniform filter cake layer during filtration, it is convenient to wash the filter cake by introducing washing liquid into the machine. If the filter cake is washed by the method of top spraying, the washing liquid can be greatly saved.

9. If you want to get a dry filter cake, after filtration or washing and filtration, enter room temperature air, hot air or steam into the machine, so that they can pass through the filter cake layer until the filter cake reaches the required dryness, and then release the pressure in the machine, and blow back the filter cake to discharge from the bottom.

10. According to the needs of customers, the machine can be operated manually or by PLC programmable controller to implement the automatic operation of the entire filtration process.

11. The slurry can be filtered into a filter cake, and it can also be used for continuous thickening and concentration of materials.

12. By using corrosion-resistant stainless steel, lined with titanium, PTFE and spraying Teflon, polyethylene, etc., the machine has high corrosion resistance to meet the material filtration requirements of strong corrosion.

13. The safety performance of this machine is good, the system is equipped with a safety discharge system, and there is no danger in operation.

14. The unique filter element detection system can easily detect the damaged filter element, and it is not necessary to check all the filter elements.

15. The unique filter element structure makes the filter cake can be stably attached to the filter bag and will not fall off during the filtration process.

Typical applications for candle filters:

|

1. Petrochemical industry: Filtration of synthetic ammonia decarburizers Filtration of caprolactam refining liquid Filtration of PTA mother liquor Recycling filtration of PVC |

2. Coal chemical industry: Filtration of methanol liquid in low-temperature methanol washes

|

|

3. Fine Chemicals: Catalyst recovery filtration Recovery and filtration of titanium dioxide in TiO2 wastewater

|

4. Chemical fiber: Filtration of viscous acid baths Filtration of condensate

|

|

5. Metal smelting: Recovery of precious metals

|

6. Sugar Production: Filtration of a carbon juice |

|

7. Oil Making: Filtration of decolorizing agents |

8. Pharmaceutical industry: Activated carbon separation filtration

|

|

9. Natural Gas: Removal of hydrogen sulfide, etc

|

10. Environmental Protection: Treatment of slag-containing wastewater |

Previous article

Next article

undefined

Focus on us

Public Number

Tiktok

Quick Hands

Product display

Contact Information

Address: 909C, Huangpu Road, Dalian High-tech Park, Liaoning Province

Telephone:13700091519/13941100988

All Rights Reserved © Liaoning Lanhai Chuanliu Fluid Control Equipment Co., Ltd.

Right online agent component